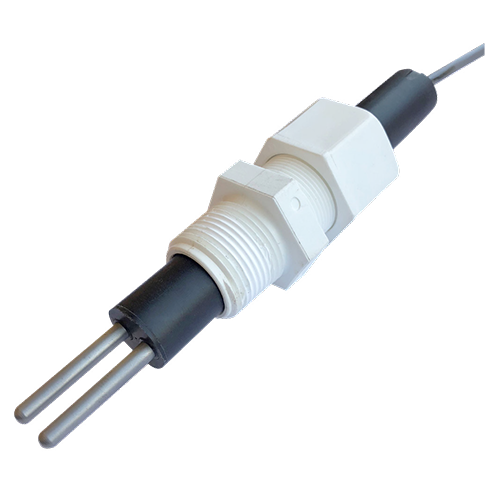

Linear polarization resistance (LPR) is an electrochemical technique used to monitor corrosion in several industrial systems, piping, cooling towers, and more that are exposed to the flow of conductive water. This is done with LPR corrosion probes or sensors, which measure the rate of corrosion. Walchem offers LPR sensor input/output cards in equipment capable of feeding chemicals for corrosion control, especially in cooling towers. The electrodes used on these sensors must be the same material as those in the system.

Key Benefits:

- Reliable 4-wire design

- Corrosion Rate and Imbalance

- Dual corrosion sensor input

- Automatically measures conductivity and compensates for it each cycle

- Able to set a control delay during the initial stabilization time

- Automatic electrode replacement reminder

- Disturbance Control Algorithms that take advantage of the corrosion signal

– Target PPM mode with Disturbance

– Adjusts the target PPM higher if corrosion increases - On/Off Disturbance mode

– Adjusts the target PPM higher if corrosion increases

For more information, please contact Walchem at 508-429-1110.

Take control and connect with the best.

An Overview of Our Cooling Tower Corrosion Sensors

Linear polarization or plane polarization occurs when an electromagnetic wave propagates in the same plane in a single direction. The resistance to this polarization is used to measure corrosion rate with the help of these probes. The probes use the LPR technique to measure corrosion resistance, wherein voltage is applied to the electrodes. They are scanned considering a certain range which may be from 0-2 mm/year to 0-200 mm per year. The voltage produces current which is used for calculating polarization resistance. This resistance is inversely proportional to corrosion rate. Hence, if the polarization resistance is low, the corrosion rate is high.

Key Benefits and Features of Our LPR Corrosion System

Our LPR sensors have benefitted several cooling towers and related applications in controlling corrosion. Here are some of their beneficial features.

- The body of these probes is made of glass-filled reinforced propylene, while the O-ring is made of FKM.

- We sell the metal electrodes separately as well.

- The controllers have a dual sensor input board which allows the measurement of corrosion for two different metals.

- These sensors are a cost-effective solution for accurately determining the corrosion rate and imbalance.

- Our corrosion detection sensors measure conductivity automatically and compensate for the same for each cycle.

- We have the initial stabilization time feature that delays control until the sensor is reading accurately.

- They can self-diagnose any issue and hence do not need a test probe simulator.

- The system can control corrosion effectively using disturbance control algorithms that ramps up the concentration of corrosion inhibitor if the corrosion rate increases.

Applications of LPR Probes

Here are some application areas of our LPR sensor.

- Cooling towers

- Industrial water processing

- Domestic water treatment

At Walchem, we have always offered advanced sensing and communication technologies to the water treatment industry. Walchem sensors are proven to cut down on the corrosion rate. If you have any questions regarding our LPR corrosion detection sensors, their types or custom options feel free to reach us at 508-429-1110. You can email us at cs@walchem.com, if you have any questions about our LPR corrosion probes.