Various chemicals such as chlorine and bromine are used in specific limits in water treatment. However, if used in large or insufficient amounts they may affect human health. This is why disinfection sensors are used to detect the level of oxidizers in water treatment processes. Walchem offers various types of disinfection sensors that can successfully detect the level of a number of chemicals. Our amperometric disinfection sensors offer a cost-effective and reliable solution to your disinfection control requirements. They are compatible with all our controllers, and continuously and directly measure the chemical concentration, without the use of reagents.

Key Benefits:

We offer sensors, in varying ranges of concentration, for free chlorine/bromine, total chlorine, chlorine dioxide, ozone, peracetic acid and hydrogen peroxide. Whether the application is a cooling tower, food and beverage, drinking water, wastewater, or swimming pool, these sensors are the ideal solution.

Low maintenance – no costly reagents or tubing to replace

Broad range of applications – wide variety of oxidizers and measurement ranges

Fast response – continuous measurement technique

No waste – the sample can be returned to the process

Categories of Disinfection Sensors

We offer sensors with and without membranes to detect varying ranges of concentration of chemicals such as free chlorine/bromine, total chlorine, chlorine dioxide, ozone, peracetic acid, chlorine gas, sodium hypochlorite, calcium hypochlorite, stabilized bromine products, and ozone among others. Here are two broad categories of disinfection temperature sensors we offer.

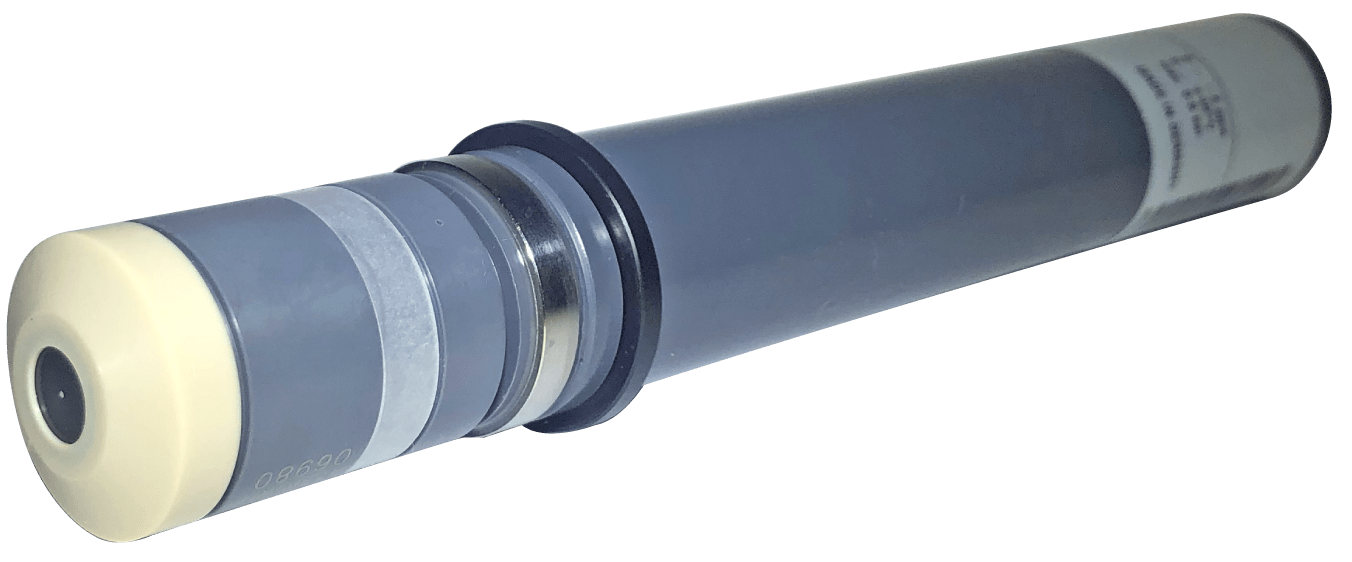

- Membrane sensors: Membranes may be either hydrophilic or hydrophobic, and may or may not be porous. Each sensor has the membrane and internal electrolyte required to perform its intended function.

- Non-membrane sensors: Walchem offers non-membrane chlorine and chlorine dioxide sensors that comprise an amperometric sensor assembly, cable, and a flow cell. They measure the disinfectant level in drinking water. The disinfection of hot potable water systems as currently required by the new ASHRAE standards is up to 70 °C (158 °F), especially for hospitals, schools, and universities.

Types of Disinfection Sensors We Offer

Here are some types of sensors we offer based on the chemicals they can measure.

- Chlorine sensors: Our chlorine sensors measure a wide range of concentrations of chemicals in water, and indirectly help prevent the growth of microorganisms. This is done without the use of reagents. These amperometric chlorine sensors can be used with all of our controllers for chlorine residual measurements in accordance with EPA Method 334.0.

- Chlorine dioxide sensors: These are specialized sensors used to measure the concentrations of chlorine dioxide in water.

- Stabilized bromine sensors: The sensors continuously and directly measure the chemical concentration, without the use of reagents. These sensors can work effectively even where ORP sensors and other amperometric sensors cannot reliably and repeatedly measure bromine that is stabilized with sulfamate. These are amperometric 3-electrode sensors and are widely used for cooling tower applications. They can withstand temperatures up to 45 °C (113 °F) and pressure up to 90 psi.

- Total Chlorine: Our total chlorine sensors use microporous, hydrophilic membranes that allow measurement of all chlorine molecules, free or combined.

- Peracetic Acid: The peracetic acid sensors are frequently used in food processing applications and can measure up 20,000 mg/l in water with a pH below 6.

Non-Membrane Disinfection Sensors

- The disinfection of hot potable water systems as currently required by the new ASHRAE standardsUp to 70 °C (158 °F)Hospitals, schools, universities

- High pressure sample loops where the water cannot be discharged to open atmosphere

- Up to 8 bar (117 psi)

- Hot tubs, cooling towers

Featuring:

- Free Chlorine and ClO2 sensors

- Designed for higher pressure and temperature, clean water applications

- Amperometric 3-electrode sensors

- The measuring and counter electrodes are in direct contact with the sample

- The reference electrode is isolated from the water by an electrolyte-filled housing

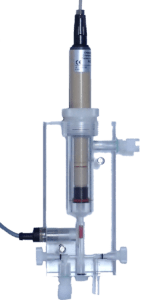

NEW!

Walchem Disinfection Flow Cell

- Fraction of the price of previous matched design

- Drop in replacement to older units

- Accepts both U.S. & metric tubing

- Designed, developed & made in the USA

- Works with Non-Membrane Disinfection Sensors

Stabilized Bromine Sensors

Walchem’s Stabilized Bromine Sensors offer a cost-effective and reliable solution to your control requirements. The sensors continuously and directly measure the chemical concentration, without the use of reagents. Where ORP sensors and other amperometric sensors cannot reliably and repeatably measure bromine that is stabilized with sulfamate, this sensor can!

Key Features of Membrane and Non-Membrane Disinfection Sensors

Here are some beneficial features of both these types of sensors.

Membrane Sensors

Whether the application is a cooling tower, food and beverage, drinking water, wastewater, or swimming pool, these sensors offer an accurate output. Here are some beneficial features of our membrane sensors.

- They are low on maintenance and cost effective as they do not require expensive reagents or tubing replacements.

- You can use them for a broad range of applications with a wide variety of oxidizers and measurement ranges.

- They offer a fast and accurate response even when used for continuous measurement.

- The sample taken is not wasted as it can be returned to the process after testing.

Non-Membrane Disinfection Sensors

Here are some benefits of using non-membrane sensors, especially for chlorine applications and high pressure sample loops where the water cannot be discharged to open atmosphere.

- These sensors are extremely efficient when measuring free chlorine and ClO2 levels in drinking water.

- Non-membrane amperometric chlorine sensors can be used for chlorine residual measurements in accordance with EPA Method 334.0.

- An electrical signal which is proportional to the concentration of the disinfectant is generated at the measuring electrode. The measuring signal is temperature compensated.

- Amperometric sensors perform best in drinking water or any clean water application with near neutral pH, and are typically used in higher pressure and/or temperature installations.

- These are amperometric 3-electrode sensors, wherein the measuring and counter electrodes are in direct contact with the sample.

- These sensors can withstand pressure up to to 8 bar (117 psi).

- The reference electrode is isolated from the water by an electrolyte-filled housing.

Applications of Disinfection Sensors

Here are some application areas of our disinfection sensors, depending on their type.

- Drinking water

- Food processing

- Reuse and process water

- Swimming pools

- Cooling towers

- Bottle washing

If you need to measure the chemical levels in your process or even drinking water, these disinfection sensors are extremely useful. They are an integral part of our water treatment controllers. Walchem is a reliable manufacturer of various types of disinfection sensors that can be integrated to water treatment controllers as part of an effective water treatment process. We ship these sensors individually or along with controllers across the globe and offer fast turnaround times. These can be customized to suit specific client requirements. If you have any questions regarding our disinfection sensors of any type, feel free to contact us at 508-429-1110, and we will be happy to assist!