In the world of industrial processes, precision, reliability, and safety are paramount. And when it comes to handling corrosive and challenging substances like Sodium Hydroxide, having the right pumping solution is non-negotiable. Sodium hydroxide, chemically written as NaOH, is a chemical used in the manufacturing of myriad products and across industries. Sodium hydroxide can be used to develop cleaning solutions and in material development. If you are seeking a pump for processing sodium hydroxide, Walchem offers a range of pumps for sodium hydroxide applications.

Importance of Sodium Hydroxide Dosing

Sodium hydroxide, commonly known as caustic soda, is a highly versatile chemical used in industries such as water treatment, chemical manufacturing, and food processing. The precise dosing of sodium hydroxide is essential for maintaining pH levels, neutralizing acidity, and facilitating various chemical reactions. Sodium hydroxide pumps ensure the accurate delivery of this chemical, contributing to the efficiency and success of diverse processes.

Choosing a Sodium Hydroxide Industrial Pump

Sodium Hydroxide, commonly referred to as lye or caustic soda, is an inorganic compound characterized by a potent metallic base. Available in various forms such as granules, pellets, flakes, and solutions with diverse concentrations, this chemical’s weight can vary based on concentration and temperature.

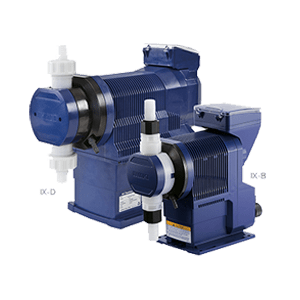

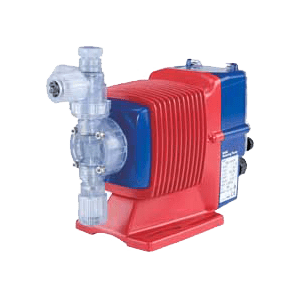

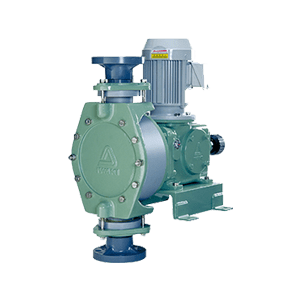

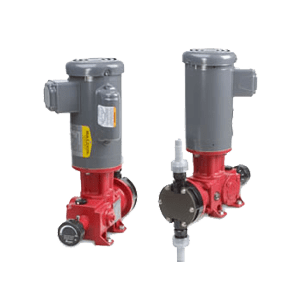

For those seeking suitable pumps for handling Sodium Hydroxide, the following chemical pumps serve as a valuable starting point:

Key Features of Walchem’s Sodium Hydroxide Dosing Pump

Cutting-Edge Technology: At Walchem, we pride ourselves on leveraging cutting-edge technology to engineer pumps that exceed industry standards. Our pumps are a testament to our commitment to innovation. Employing state-of-the-art materials and design, these pumps are built to withstand the harshest operating conditions.

Corrosion Resistance: One of the primary concerns when dealing with Sodium Hydroxide is corrosion. Our pumps are constructed with corrosion-resistant materials, ensuring longevity and reliability even in the most corrosive environments. Say goodbye to frequent replacements and maintenance issues – Walchem pumps are built to last.

Precise Metering: Accurate dosing of Sodium Hydroxide is critical for many industrial processes. Walchem’s pumps are engineered for precise metering, providing a level of accuracy that is unmatched in the industry. This precision not only enhances the efficiency of your operations but also contributes to cost savings.

Versatility: Walchem understands that every industrial process is unique. That’s why our Sodium Hydroxide Pumps are designed with versatility in mind. Whether you need a pump for a small-scale operation or a large industrial plant, Walchem has a solution tailored to your specific requirements.

User-Friendly Interface: Ease of use is a key factor in the success of any industrial equipment. Walchem’s Sodium Hydroxide Pumps feature a user-friendly interface, making them easy to install, operate, and maintain. Our commitment to user convenience ensures that your team can focus on what matters – efficient production.

Real-world Applications

Water Treatment

In the realm of water treatment, precision and reliability are non-negotiable. Walchem’s Sodium Hydroxide Pumps play a crucial role in pH adjustment, ensuring that water treatment processes meet regulatory standards. The pumps’ accuracy and dependability contribute to the overall effectiveness of water treatment plants.

Chemical Manufacturing

Chemical manufacturing processes demand pumps that can handle corrosive substances with finesse. Walchem’s pumps are up to the challenge, delivering the precision required for accurate chemical dosing. From small-scale batch production to large-scale manufacturing, Walchem pumps excel in diverse chemical applications.

Industrial Waste Management

Efficient handling of Sodium Hydroxide is essential in industrial waste management. Walchem’s pumps facilitate the precise dosing of Sodium Hydroxide in neutralization processes, ensuring the safe and effective treatment of industrial waste streams. Our pumps contribute to environmental sustainability by optimizing the use of chemicals in waste treatment.

FAQs Sodium Hydroxide / Caustic Soda Pumps

What is a Caustic dosing pump, and how does it work in industrial processes?

A sodium hydroxide pump is a device designed for the controlled dosing of sodium hydroxide into industrial processes. It works by injecting a predetermined amount of sodium hydroxide to maintain pH levels, neutralize acidity, and facilitate chemical reactions.

Why is a caustic metering pump essential in industrial applications?

Sodium hydroxide pumps are crucial in industries as they enable precise dosing, ensuring optimal pH levels and chemical reactions. This is vital for processes ranging from water treatment to chemical manufacturing.

Can caustic soda dosing pump be used in various industrial processes?

Absolutely. Sodium hydroxide pumps are versatile and can be customized to suit the specific needs of diverse industries, making them suitable for applications ranging from water treatment to chemical manufacturing.

How do sodium hydroxide pumps contribute to cost-effective operation?

Sodium hydroxide pumps contribute to cost-effective operation by providing precise dosing, minimizing chemical wastage, and optimizing overall efficiency in industrial processes. This results in significant cost savings over time.