Liquid ammonia, chemically represented as NH3, is a crucial substance in industrial settings, primarily utilized in its liquid form due to its ease of handling and diverse applications. Created through the compression and cooling of gaseous ammonia, liquid ammonia is a colorless, pungent-smelling chemical, offering a range of unique properties and chemical reactivity. Unlike its gaseous state, which is commonly encountered at room temperature, liquid ammonia is utilized for its stability and ease of transport, making it an indispensable component in various industries.

Liquid ammonia serves as a cornerstone for various processes and applications across multiple sectors. The diverse uses, characteristics and responsiveness of this substance make it a crucial element, in sectors like farming, chemical production cooling systems and cleaning tasks.

Choosing a Liquid Ammonia Pump

In industries where liquid ammonia plays a role picking the pump is essential to ensure smooth operations top notch performance and safety. The decision on an ammonia pump involves evaluation of different factors to meet specific application requirements and adhere to industry norms. Here are key factors to consider when choosing a pump:

Compatibility with Materials: Liquid ammonia is reactive chemically and can cause corrosion in certain materials. When selecting a pump, it’s vital to opt for materials that work well with ammonia to prevent corrosion and ensure durability in the run. Materials like steel, nickel alloys and specific plastics are commonly utilized for pump parts in systems handling ammonia.

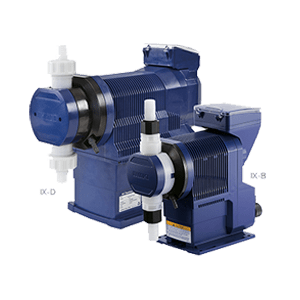

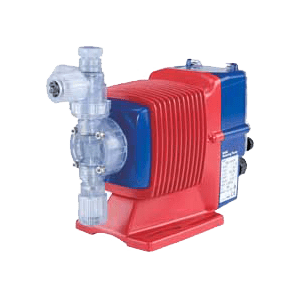

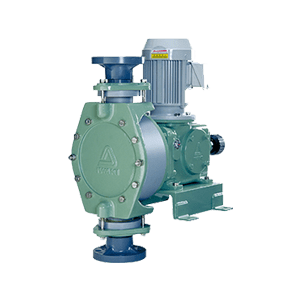

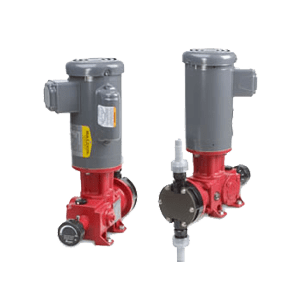

Design and Construction: The design and structure of the pump should meet requirements, for efficiently managing liquid ammonia. Make sure to search for pumps, with build quality seals that prevent leaks and special coatings or linings to guard against corrosion and wear. Also take into account aspects like the type of pump (such, as centrifugal, diaphragm or positive displacement). Operational features designed to meet the needs of the application.

Performance Specifications: Evaluate the pump’s performance specifications, including flow rate, pressure capacity, and temperature range, to ensure compatibility with the intended application. The pump should be capable of delivering the required flow rate and pressure to meet process demands while operating within the safe temperature range for handling liquid ammonia.

Safety Features: Safety is paramount when handling hazardous chemicals like liquid ammonia. Choose a pump equipped with built-in safety features, such as overload protection, leak detection systems, and emergency shutdown mechanisms, to mitigate the risk of accidents and ensure personnel and asset safety. Compliance with industry standards and regulations, such as those outlined by regulatory bodies like OSHA and EPA, is essential.

What Industries and Applications Handle Liquid Ammonia?

Liquid ammonia, with its unique properties and versatility, finds extensive use across a spectrum of industries, ranging from agriculture to manufacturing and beyond. Let’s explore the diverse industries and applications where liquid ammonia plays a pivotal role:

Agriculture

- Fertilizer Production: Liquid ammonia serves as a primary precursor in the synthesis of nitrogen-based fertilizers, including ammonium nitrate, urea, and ammonium phosphate. These fertilizers are essential for providing crops with the necessary nitrogen nutrients, promoting healthy growth, and increasing agricultural productivity.

Chemical Manufacturing

- Synthetic Chemistry: Liquid ammonia is a key reagent in various chemical synthesis processes, facilitating the production of a wide range of chemicals and intermediates. It serves as a versatile solvent, reactant, and reducing agent in organic and inorganic synthesis, enabling the manufacture of pharmaceuticals, polymers, plastics, dyes, and specialty chemicals.

- Nitric Acid Production: Liquid ammonia is utilized in the catalytic oxidation of ammonia to produce nitric acid, a critical precursor in the manufacture of fertilizers, explosives, and industrial chemicals. The Haber-Bosch process, which converts nitrogen and hydrogen into ammonia, forms the basis for nitric acid production from liquid ammonia.

Cleaning and Decontamination

- Industrial Cleaning: Liquid ammonia’s alkaline nature and excellent solvent properties make it an effective cleaning agent for industrial equipment, machinery, and surfaces. It is utilized in degreasing, descaling, and decontamination processes across various industries, including automotive, aerospace, food processing, and pharmaceutical manufacturing. Liquid ammonia-based cleaning solutions efficiently remove grease, oil, carbon deposits, and other contaminants, ensuring equipment reliability and product quality.

Water Treatment

- pH Adjustment: Liquid ammonia is employed in water treatment processes as a pH regulator and alkalinity adjuster. It helps maintain optimal pH levels in water treatment systems, such as potable water treatment, wastewater treatment, and industrial process water treatment. Liquid ammonia-based solutions are used to neutralize acidity, control alkalinity, and optimize water chemistry for various applications.

Unraveling the Walchem Advantage

At Walchem, we understand the intricate demands of chemical manufacturing like no other. With decades of experience and a relentless commitment to technological advancement, we have engineered a liquid ammonia pump that stands head and shoulders above the rest. Let’s delve into the features that define the Walchem advantage:

Unparalleled Performance

- Walchem’s Liquid Ammonia Pumps boasts exceptional performance metrics, ensuring seamless operation even under the most demanding conditions.

- With optimized flow rates and pressure capabilities, our pumps guarantee consistent and precise handling of liquid ammonia, empowering your processes to achieve peak efficiency.

Cutting-Edge Technology

- Leveraging state-of-the-art engineering and innovative design principles, Walchem has developed pumps that redefine industry standards.

- Advanced materials and precision manufacturing techniques enhance durability and reliability, minimizing downtime and maintenance costs.

Superior Safety Standards

- Safety is non-negotiable in industrial settings, and Walchem prioritizes it above all else.

- Our Liquid Ammonia Pumps incorporate robust safety features and failsafe mechanisms to mitigate risks and safeguard personnel and assets.

Versatility and Adaptability

- Recognizing the diverse needs of our clientele, Walchem pumps are engineered for versatility and adaptability across a wide range of applications.

- Whether it’s chemical processing or industrial cleaning, our pumps delivers unparalleled performance, ensuring seamless integration into your operations.