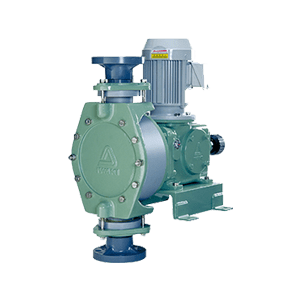

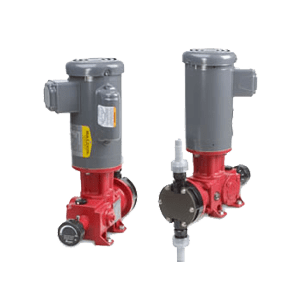

Walchem Chemical Metering Pumps – LK and LKN Series

LK and LKN Series Chemical metering pumps are mechanically actuated, motor driven diaphragm pumps that are used for accurate chemical dosing in various industrial applications. Repeatable dosing enables these pumps to dispense chemicals proportionally, in calculable volumes or transfer in specific doses. At Walchem, we offer a variety of premium quality chemical metering pumps such as the LK and LKN series metering pumps. The LKN series pump is the largest in the high-performance line of pumps from Walchem. It is a motor-driven, mechanically actuated diaphragm metering pump with a maximum capacity of 114 GPH (432 l/h) and a maximum pressure of 225 PSI (1.5 MPa). The larger LK Series can achieve outputs up to 856 GPH (3240 l/h) and maximum pressures of 220 PSI (1.5 MPa). The LKN series motor driven metering pumps come with the NEMA 42C motor mounting flange but can be adapted to 56C motors. Both these pump series are from the same family and are similar in design, however, they are unique in some features, capacity, and configurations.

Operating Principle of LK and LKN Series Motor Driven Metering Pumps

These pumps are made from three main sections – the liquid end, the gearbox drive unit, and the drive or motor. The liquid end is comprised with a pump head, diaphragm, ball check valves, valve seats, discharge port, and suction port. The drive design uses an armature, spring, control shaft, stroke length dial, worm wheel shaft, cams and slider. The worm and wheel shaft reduce the rotary speed of the motor and the rotary motion is converted into reciprocating motion through the cams & slider. The armature then transmits the reciprocating motion to the diaphragm through the armature shaft. As the diaphragm moves in and out, the volume inside the pump head chamber changes and the suction or discharge valves actuate depending on the direction of the diaphragm, creating controlled displacement of fluid through the pump. The total diaphragm stroke length can be adjusted to vary the volume per stroke by turning the stroke length dial on the control shaft. With this, you can adjust the flow rate between 0 and 100% of pump rated output.

Features of LK Series Motor Driven Metering Pumps

Using high precision and a robust design, the LK Series have proven to one of the most reliable pumps in the Walchem portfolio. The LK Series mechanically actuated diaphragm pumps have many beneficial features:

- The LK series pumps are high performing pumps with a versatile design. They have a discharge accuracy rating of ±2% FS considering continuous operation or repeated dosing.

- The robust design of these pumps enables the transfer of rotational force from the motor to the diaphragm via a compact drive unit. This economical design ensures reliability, quality, performance, and ease of operation.

- These pumps come with a dual-cam drive gear box and a built-in worm gear type speed reducer. This compact & rigid mechanism, provides maximum wear resistance in continuous operation over long periods of time.

- These pumps are available in various sizes to fit ranges from small to very large injection flow rates. Wetted materials are available in various materials including PVDF, PVC, 316SS stainless steel, Alumina Ceramic, fluoro-rubber (FKM), ethylene propylene rubber (EPDM), and Hastelloy C276, depending on the model. These materials make the pumps resistant to acids, alkalis, viscous fluids and slurries, caustic soda, solvents, and chemicals.

- These pumps, regardless of the configuration, integrate precision in the engineering design coupled with oversized bearings and materials for complete reliability a high compression ratio for stroke accuracy and pump linearity.

- The large LK series is categorized into LK-A, LK-B, and LK-C series pumps based on the motor code each with different capacities, stroke speeds, and maximum pressure capability.

- They can be fitted with IEC flanged general-purpose or TEFC outdoor-use vertically mounted motors. Motors are available in various voltage and enclosure options, including VFD-ready and explosion-proof designs.

Features of LKN Series Motor Driven Metering Pumps

Here are some beneficial features of the LKN series chemical metering pumps.

- The “N” in LKN series pumps denotes a unique version for a NEMA 42C motor mounting flange. There various LKN series model have different maximum pressure and flow capacities, stroke speeds, and NPT connections. Capacities range from 30 to 380l/h and have stroke speeds at 58 or 116spm, depending on the frequency.

- These are motor-driven, mechanically actuated diaphragm metering pump with a maximum capacity of 114 GPH (432 l/h) and a maximum pressure of 225 PSI (1.5 MPa).

- Liquid ends in a pump are components that draw the liquid inside and push it through the pump at the preset or required flow rate and pressure. The liquid ends in these pumps are versatile and made of PVC, PVDF and 316SS stainless steel which is best suited to handle acids, bases, solvents, polymers and slurries.

- The stroke length adjustment in the pumps provides accurate adjustment with a micrometer dial to change the output per stroke of the pump. The stroke length adjustment mechanism is lockable and adjustable from 10 to 100%.

- They have a dual-cam system drive with a built-in worm gear type speed reducer. The aluminum bronze worm gear and the robust tapered roller bearing provide efficient transmission of motor power to the pump.

- Many of the LKN standard models have totally enclosed and vertically mounted fan-cooled motors, which helps save space. We offer various types of motors, including VFD-ready, explosion-proof and DC variable speed motors for external control by a 4-20 mA input signal.

Applications of LK and LKN Series Pumps

Top application areas for our motor driven diaphragm pumps include, but are not limited to:

- Water treatment

- Wastewater treatment

- Chemical process

- Agriculture

- Mining

- Pulp and Paper

- Truck wash

- Stormwater Remediation

If you require mechanically actuated diaphragm pumps for your application, the quality and reliability of the LK and LKN series chemical pumps cannot be beat. Walchem offers solutions for most metering pump applications and installations. Many required pump and pump safety accessories for installation are also available. Without compromising quality, Walchem can offer custom options and fast turnaround times. If you have any questions regarding Walchem’s LK and LKN series motor driven diaphragm pumps, require further information, or want to share your requirements, please contact us via phone at 508-429-1110, or email at cs@walchem.com.