Key Benefits:

- Large touchscreen display with icon based programming makes setup easy

- Two sensor input slots provide extraordinary flexibility; the same controller can be used with almost any type of sensor needed

- Copper or Nickel plus pH

- Dual analog inputs for any 4-20 mA transmitter

- Universal analytical sensor card for pH/ORP, conductivity or disinfection

- Combination analog input and analytical sensor input

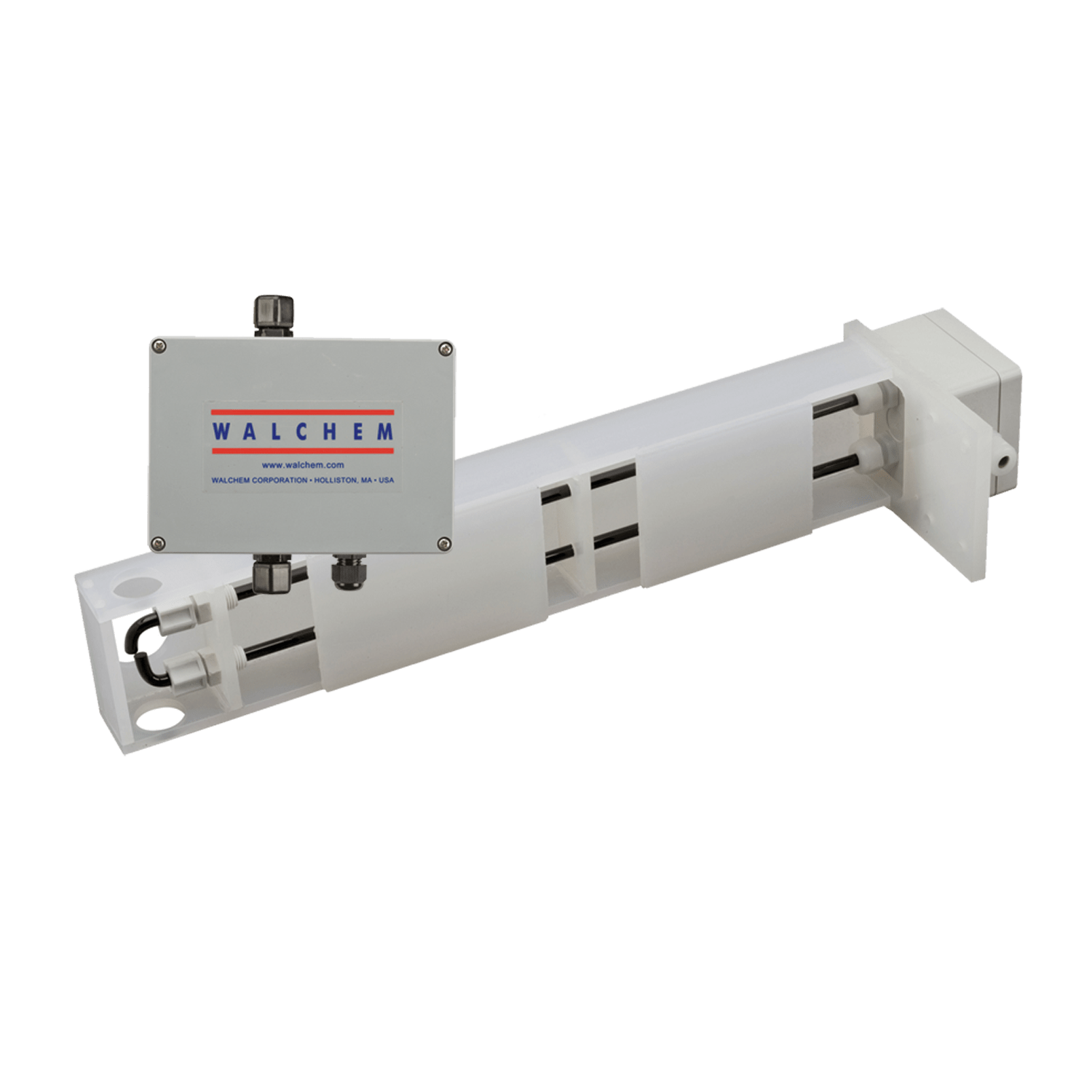

- Accurate and reliable photometric sensors

- Six relay outputs, six virtual inputs, and six virtual outputs

- Multiple language support allows simple setup almost anywhere in the world

- Economical wall-mount package for easy installation

- On-screen and web page graphing of sensor values and control output status

- Email alarm messages, datalogs, graphs, or system summary reports

- Ethernet option for remote access via the Internet, LAN, BACnet or Modbus/TCP