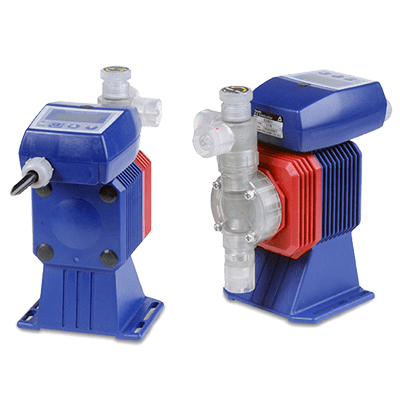

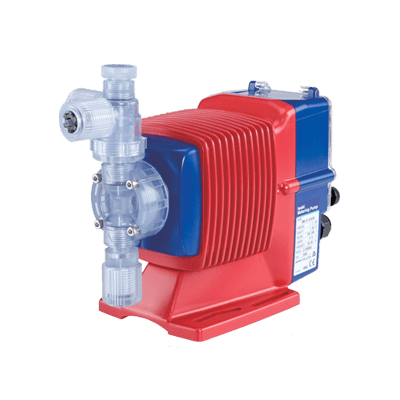

EZ Series

Proportional Feed Metering Pumps

Walchem metering pumps are ideal for these applications due to the high-speed pump operation and simple interface with controllers and flowmeters.

Customer | Water Treatment

PROBLEM

Walchem receives frequent calls from customers asking for help setting up their water treatment system for proportional control. Do these two situations sound familiar?

SOLUTION

Situation 1: A water doctor is feeding inhibitor based on a water meter input in his INT -9 Cooling Tower Controller and wants to know how to program the controller to give him an injection rate of 17 ppm. He has a WFM071-0G100 that provides one pulse for every 100 gallons of make-up water and an EZB11D1-VC pump adding inhibitor.

Solution 1:

The EZB11D1-VC metering pump is controlled by the feed relay of the cooling tower controller. To determine how to program the controller to achieve the desired result, the customer should use the following formula:

(Gallons of water x 0.3785 x PPM Injection rate)

Chemical concentration (whole#) x Specific Gravity =ml of chemical feed

For this example: (100 gallons x 0.3785 x 17 PPM)

100 (% concentration) x 1.3 = 4.9 ml of chemical feed

Chemical injection rates for cooling tower and boiler chemicals are generally determined assuming a 100% chemical concentration. Since the pump is an EZB11D1-VC with output of 38 ml/minute (0.106 ml/stroke), the customer will need about 46 strokes to achieve the desired injection rate (4.9 ml of chemical feed ÷ 0.106 ml/stroke = 46 strokes). Therefore, the pump should be programmed to come on for 46 strokes or 8 seconds (if the pump is operating at 360 strokes per minute) for every pulse input.

Situation 2

A water treatment plant is adding 12.5% sodium hypochlorite to potable water for disinfection. They have done a water analysis and know that they need to inject at a rate of 6 ppm to achieve a residual of 0.5 ppm. They have a maximum flow rate of 100 GPM and have a WFM201-0G10 flowmeter that provides one pulse for every ten gallons of water. They want to know how to program their EWN-B16VCURC pump to achieve the desired injection rate.

Solution 2

EWN-B16VCURC metering pump should be connected directly to the WFM water meter for flow proportional control. Here’s the formula to determine the required chemical feed in ml/gal:

0.3758 x PPM injection rate = ml/gallon of chemical feed

(Chem. Concentration (whole#) x Specific gravity) To determine the ml/contact from the pump, find the contact ratio of the flowmeter and use this formula: ml/gallon x gallons/contact = (ml/contact)

To determine metering pump strokes/contact, find the ml/stroke from the metering pump and use this formula: ml/contact ml stroke or ml contact x stroke ml = strokes contact

If the resulting number of strokes per contact is 1 or over, enter the closest whole number using the multiply feature. If the number is less than 1, take the reciprocal of the number (1/number) and enter it as the divide number .

(0.3785 x 6 PPM injection rate) (12.5×1.2 )= 0.15 ml/gallon of chemical feed.

(0.3785 x 6 PPM injection rate) (12.5 x 1.2) = 0.15 ml/gallon of chemical feed

For this example: 0.15 ml (gallon) x 10 gallons (contact)= 0.15 ml/gallon of chemical feed

1.5ml (contact) x (stroke) 0.16ml* = 9.4 strokes (contact)

*Max output of EWN-B16VCURC =0.16 ml/stroke at 100% stroke length

In this application, the multiplier number on the EWN-B16VCURC would be set to 9 (or 10 depending on actual pump output)

All of these equations will get you close to your desired injection rates for proportional feed applications. It will sometimes be necessary to fine-tune the controllers or pumps by adjusting on-times the Multi/Divide numbers or stroke length to achieve the desired results. Calibration of the pumps into the actual application (use of calibration columns) is recommended for the most accurate results.

Useful conversions: 1 US gallon = 3.785 liters = 3785 ml

1 Liter + 1000 ml

1part per million (ppm) + 1 mg/L + 0.0038 ml/gallon

1 fluid ounce = 29.6 ml/

WHERE TO FIND SIMILAR COMPANIES-SITUATIONS:

Everywhere! Walchem metering pumps are ideal for these applications due to the high-speed pump operation and simple interface with controllers and flowmeters.