Intuition-9

Wet Air Scrubbers

The Walchem Intuition-9 controller provides integrated monitoring, remote access, and automated chemical dosing for wet air scrubbers, reducing maintenance costs and increasing performance.

Customer | Wet Air Scrubbers I Industrial Gas Cleaning

APPLICATION

Wet air scrubbers (WAS) are used across multiple industries, primarily for odor, dust and noxious chemical removal from exhaust streams. These systems function similarly to cooling towers in design but are used primarily to absorb or react with airborne contaminants through dispersed water droplets.

Most WAS designs are countercurrent, with water sprayed from the top while air is pushed from the bottom. Like cooling towers, wet air scrubbers face challenges such as scaling, corrosion, and biological growth. However, they also contend with additional issues, including pH variability of the gases and retention of odorous compounds. These problems are commonly managed through chemical treatment, including oxidants like chlorine, chlorine dioxide, and ozone. Additionally, biological treatment methods using bacteria to break down contaminants are gaining popularity.

pH, conductivity, and oxidation-reduction potential (ORP) are key parameters in wet air scrubber operation. Chemical dosing may involve sulfuric acid, caustic, nutrients for bacteria, and scale/corrosion inhibitors

PROBLEM

Wet air scrubbers require precise and continuous monitoring to ensure optimal performance and regulatory compliance. Key challenges include

• Maintaining proper pH, ORP, and conductivity levels to prevent scaling and corrosion.

• Managing chemical dosing efficiently to minimize waste and costs.

• Ensuring remote accessibility for troubleshooting and adjustments, especially for units shipped globally.

• Integrating multiple sensors, pumps, and other equipment into a centralized control system.

Traditional PLCs and standalone controllers often lack cost-effective remote access capabilities and seamless integration of multiple inputs, making it difficult to manage scrubbers in remote or international locations.

SOLUTION

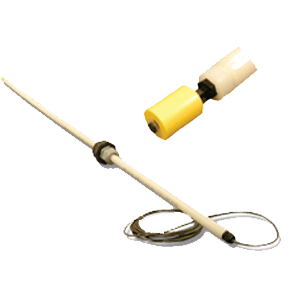

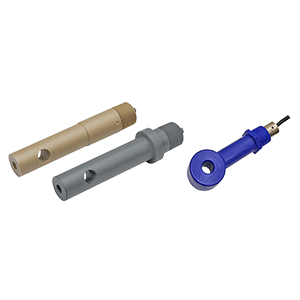

The Intuition-9 controller is an ideal solution for wet air scrubbers, offering integrated sensors, precise chemical feed control, and additional digital and analog inputs for flowmeters, level sensors, and chemical pumps. Walchem provides a range of reliable sensors, including the WDS pH/ORP series and electrodeless conductivity sensors designed for demanding requirements. The robust WDS differential pH and ORP electrodes ensure long-lasting, reliable performance, with easily replaceable reference electrodes. Additionally, Walchem toroidal conductivity sensors resist thin coatings and contamination, eliminating calibration issues common with direct-contact sensors, making them ideal for the severe conditions in wet air scrubbers.

The EZ series of dosing pumps offer precise chemical injection at a low cost. The compact size and simple control make them ideal for this OEM style application.

The Intuition-9 provides comprehensive historical data logging for quick diagnostics and issue resolution. Fluent, our web-based monitoring platform, enables secure worldwide access, significantly reducing the need for on-site service. As many wet air scrubbers are shipped to international markets, the remote accessibility of the Intuition-9 offers a major advantage over traditional PLCs and standalone controllers, ensuring lower maintenance costs, improved system uptime, and enhanced customer satisfaction.

Figure 1: Wet Air Scrubber using Intuition-9

RELEVANT PRODUCTS

Walchem and our distributors can provide plug-and-play systems that incorporate the Walchem controls, sensors and metering pumps for your application. Contact us or your local distributor to learn more.