Lea atentamente las siguientes instrucciones antes de descargar su software.

Para asegurarse que su actualización del software W600 es la apropiada, vaya al menú Configuración, busque el menú Detalles del Controlador y presione entrar. Mire el nombre del producto y use solo la actualización de software que coincida con el Nombre del Producto. Para determinar la revisión de software en su controlador, vaya al menú Configuración, busque el menú Detalles del Controlador, presione entrar y busque la versión del software de la tarjeta de control. La última versión es 3.25. No realice esta actualización a menos que la versión de su controlador sea 2.01 o mayor.

¡Actualizar el software en su controlador W600 es fácil! Todo lo que usted necesita es una llave USB de 32 MB o mayor (Por favor recuerde que 16 GB es el tamaño máximo admitido)

Always upgrade to the latest version for the greatest reliability! We are continuously improving the W600! Here are the features we have included lately. Please note that if you have an early revision of the software, you may only update to the latest revision, not to any intermediate revision.

- Fixed an issue where false file system error alarms are reported in the System Log

- Added a hard-coded 60 minute time delay for reporting VTouch communications and Live Connect alarms. Short term failures will still be captured in the System Log but will not generate alarms unless the condition persists.

- Changed the color of the Min, Max, Average lines in the webpage graphs to improve visibility

- Modified copper/nickel sensor error handling to match W400 series

- New logarithmic generic sensor type for use with Ion Selective Electrodes

- New Graph type email report

- Improved Graph webpage to allow custom setting of the Y-axis scale

- Increased the maximum alarm delay time for email reports to 24 hours

- Improved anti-windup in PID control modes

- Improved reliability of the network card file system

- Added two decimal places to Flow Proportional control mode set point to allow for smaller values

- Modified Time Proportional and % Timer control modes so that set point changes take effect immediately instead of at the next time cycle

- Improved response time when using a duty cycle in On/Off control mode

- Fixed an issue where the controller doesn’t resume control in intermittent sampling if a calibration is started but never completed

- Fixed an issue where using the Smoothing Factor for disinfection or pH/ORP causes an offset in the reading.

- Fixes an issue with a false “Calculation Error” alarm that can happen on a Relay 2 Flow Timer output

- Fixes an issue where abandoning an Intermittent Sampling calibration can disable control

- Add logo, controller name and location to all webpages

- Adds new virtual input type to log or control on a sensor’s Raw Value

- Removed exponential notation in datalogs

- Immediately show new conductivity value after a calibration when using Intermittent Sampling

- Add high and low alarms for Paddlewheels

- Can now read temperature sensors even if the primary sensor is disabled

- Analog outputs forced to 0 mA during the boot up period

- Fixed an issue where Hand and Auto Output Timeouts interacted

- Widened the WCU/WNI sensor fault alarm range to prevent false alarms with long cable lengths

- Adds support for up to 8 parameters on the Home screen

- Adds links to the manual, Walchem website and VTouch from the Home webpage

- Spike set point algorithm enhancement to optionally start spike timer only after set point is reached

- Adds Flow Proportional control mode

- Adds an auto-dim option for the display backlight

- Adds a TCP Timeout setting to improve reliability of slow cell connections

- Adds an alarm delay during power up initialization period

- Adds the custom name of the relay selected on the HOA screen

- Adds a new OEM software version

- Adds a new feature to an existing OEM software version

- Fixed an issue where the pulse proportional control pulse rate could be twice the expected rate.

- Fixed an issue where the conductivity reading displayed is not updated immediately following boiler intermittent sampling if trapped sampling is disabled.

- Fixed an issue where resuming control is delayed for several seconds after a biocide bleed lockout or probe wash hold time of 0.

- Fixed an issue where an On Delay or Off Delay can stop before the programmed amount of time

- New Feed Monitor digital input type

- The feature where a biocide or timer event can be selected to occur immediately after an interlock clears has been re-named from “Interlock Delay” to “Add Last Missed”

- Conductivity-based biocide prebleeds will now be forced to have a time limit also associated, so it’s no longer possible for the prebleed to last forever

- Added an Air Calibration for contacting conductivity sensors to improve accuracy

- Modified the % Timer algorithm so that a new cycle starts if the sample period setting is changed

- Fixed an issue in W600 where Web Server Failure alarms are not cleared from the display after the alarm is cleared

- Fixed an issue in the W600 where too many timer events can result in a reboot

- Increased the maximum setting allowed for the paddlewheel K factor

- Fixed an issue in Timer control mode Hourly event repetition settings changing after a restart

- Fixed an issue where a Flow Timer control output can stop accumulating feed time if interlocked by another output

- Fixed an issue with PID control mode if the input is paddlewheel or virtual input type

- New combination Sensor Input and Analog Input board that add even more flexibility

- Modbus/TCP communications

- Graphing capability is now extended to web pages as well as the local display

- Two Virtual Inputs that are calculated from two real inputs (cycles of concentration, % rejection, etc.)

- PID control using Pulse or Analog outputs

- On and Off Delays added to some control algorithms

- Lead/Lag control of up to 6 relay outputs

- Intermittent Sampling for boilers without using a trapped sample

- Added a 2nd flowmeter input to the Feed Timer control algorithm

- Antimony pH sensor support

- Ability to restore default settings

- Chinese and Taiwanese languages

- Ability to choose to feed the last missed Biocide after an interlock

- Ability to set the flow total to match the meter’s register

- Total support for eService Reports

- Modified Bleed/Feed and % Timer algorithms so a feed cycle doesn’t begin immediately after and interlock clears

- Improved system stability

- Improved sensor speed of response

- Fixes a problem in 2.09 where Flow Based Feed will not occur after an Interlock is cleared

- Fixes a problem in 2.09 where Intermittent Sampling doesn’t operate the control valve correctly

- Fixes a problem in 2.09 where the Minimum Relay Cycle time that is used with motorized ball valves is not used correctly

This software upgrade improves performance and reliability of several existing features:

- Decreased the time required to download log files

- Improved the speed and reliability of VTouch Live Connect

- Improved the speed and reliability of all Ethernet communications

- Improved the reliability of the graph generation on the local display

- Improved the reliability of configuration file imports

- Corrected a problem loading the Display Settings menu that can occur when all possible inputs are being used

- Corrected a problem where the analog output status can be incorrect

- Improved webpage by eliminating expanding and collapsing links when hovering over them

- More System Log messages to improve diagnosis

- Improved handling of time changes in the graphs and data log files

- Improved accuracy of timers

Adds support for:

- Sending emails (alarm or datalog) directly from the W600

- LiveConnect to W600 via VTouch

- Control based on paddlewheel flowrate

- ORP Spike control mode

- Duty cycle with on/off control mode

- Easier biocide, industrial timer and probe wash programming

- Ability to download data since the last time data was downloaded, plus more flexible log lengths and time between data points

- Calibration reminder

- Automatic reset of flow total (daily, monthly, annually)

- Totalize time that a digital input (like a flow switch) has been open or closed

- 4 parameters on the Home screen

- Delay alarm notifications on system startup

- Improved Ethernet connectivity

- Fixed pulse proportional control output going below the minimum setting

- Fixed issue with changing modes from webpages when using French language

- Reduced low limit for temperature sensors to -20 C, -4 F

- Disabled the Home screen timeout during log file transfers

Adds support for:

- Automatic buffer recognition for pH calibration

- Three point buffer calibration for pH sensor

- Probe wash relay control mode

- Damping/averaging on sensor and analog inputs

- User-adjustable conductivity automatic temperature compensation %

- More flexible alarm relay control mode, able to select specific alarms that trigger the relay

- Increase paddlewheel rate to 500 Hz.

- Improvements to intermittent sampling calibration, and calibrations in general

- Reset default calibration

- Suppress sensor alarms during No Flow

- Improvements to Ethernet connection stability

- Adds support for a Generic type sensor for use with any sensor that has a linear voltage output between -2 VDC and +2 VDC. Adds two new analog input types, one for a Fluorometer Input for use with the Little Dipper 2 sensor, and one for Transmitter for use if the device connected cannot be calibrated on its own and the W600 will need to be used to calibrate in engineering units of measure. The existing Generic AI type will be renamed AI Monitor. Adds adjustment to the brightness and contrast of the display. Adds the current day of the week to the Details screen for Biocide Timer and Timer control modes. Adds a menu to cancel the remaining feed time when using Bleed Then Feed control mode. Adds a new page of special characters, mostly Greek, available for text entry in all languages. During calibrations, the sensor reading will now be displayed and the user may force the calibration to completion if the value is not sufficiently stable for the controller to continue on its own.

- First released software version

¡Actualizar el software en su controlador W600 es fácil! Todo lo que usted necesita es una llave USB de 32 MB o mayor (Por favor recuerde que 16 GB es el tamaño máximo admitido) Haga click en el link debajo para descargar el software:

- WCT600 software upgrade

- WBL600 software upgrade

- WCN600 software upgrade

- WPH600 software upgrade

- WDS600 software upgrade

- WCU600 software upgrade

- WNI600 software upgrade

- Se abrirá un cuadro de diálogo que le preguntará si desea guardar o abrir el archivo. Elija «Guardar como». En XP y Vista, guárdelo en su escritorio (esto lo hace fácil de encontrar). En Windows 7, 8 o 10, el archivo se guarda en la carpeta «Descargas».

- En XP y Vista, haga doble clic en el archivo en su escritorio para descomprimir el archivo. En Windows 7, 8 o 10 vaya a su carpeta de Descargas y extraiga el archivo (normalmente tendrá que hacer clic derecho en el archivo y seleccionar «Extraer todo»). Arrastre el archivo de actualización extraído a su escritorio.

- Conecte su llave USB. La ventana de la unidad debería abrirse. De lo contrario, vaya a «Mi PC» y ábralo (debe ser una unidad de «Medios extraíbles»).

- Arrastre el archivo llamado W**W600-v3_25.bag a la unidad USB. Asegúrese de que el archivo de actualización es el único archivo en la unidad. ** será el Nombre del producto del archivo que seleccionó.

- Desenchufe la llave USB de la computadora. Ahora puede subirlo a tu controlador.

Nota: Si tiene problemas con el circuito de red Ethernet, es posible que deba ejecutar una actualización para volver a sincronizar la tarjeta con el controlador.

Nota: Si agregó una tarjeta de sensor, entrada analógica o salida analógica anterior a un controlador con un software más nuevo, es posible que deba actualizar el software de la tarjeta de E / S.

Cargar el archivo en su controlador W600:

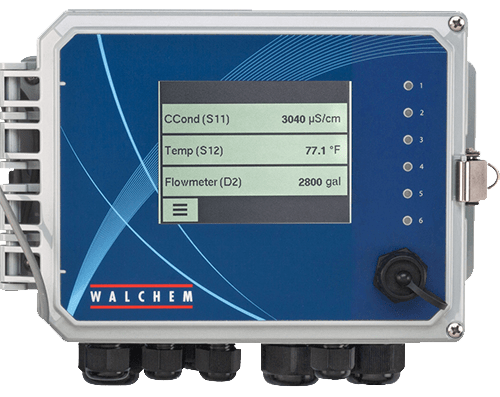

- Conecte la llave USB in el Puerto de conexión ubicado en la parte exterior en el panel frontal del controlador sobre la esquina derecha abajo, retirando la tapa a prueba de agua.

- Vaya al menú de Configuración, presione en la flecha hacia abajo para desplazarse a la última página.

- Presione en Utilidades de Archivo y luego presione la flecha hacia abajo para desplazarse a la última página

- Presione Actualización de software.

- Presione el ícono Verificar (Confirmar) para comenzar la actualización.

- El controlador mostrará el progreso en el proceso de importación de los archivos. Deje la tarjeta de memoria en su lugar. Si la instalación fue exitosa, el controlador se reiniciará automáticamente y luego se puede quitar la llave USB.

Videos